Managing domestic hot water (DHW) temperature in public buildings is a major challenge, combining health issues, regulatory requirements, user comfort and energy optimization. For ERP managers, controlling these parameters is essential to ensure occupant safety, prevent the risk of Legionnaire's disease, and reduce operating costs. Focus on the issues at stake and the solutions required for effective management.

Why monitor domestic hot water temperature?

Risks associated with unsuitable temperatures

The bacterial proliferation of legionellosis

This is one of the main threats associated with poor DHW temperature management. This serious, often fatal, infection is caused by bacteria that thrive in stagnant, warm water at temperatures between 25°C and 50°C. Legionellosis is on the list of notifiable diseases, given its potential impact on public health.

Energy waste

Unnecessary overheating wastes energy and increases energy bills. Every degree above that required translates into a significant rise in operating costs.

Discomfort and insecurity

Water that's too hot can cause burns to users, while water that's too cold can be a source of dissatisfaction. These inconveniences can affect establishments housing vulnerable populations, such as crèches, hospitals or retirement homes.

What temperature for domestic hot water?

Recommended temperatures :

- Hot water in the tank: maintaining a minimum temperature of 60°C is essential to prevent the risk of Legionnaire's disease.

- Hot water at the tap: regulations stipulate thatwater delivered at the tap must not exceed 50°C in toilet rooms in public buildings. This threshold is designed to prevent the risk of scalding, but it may prove unsuitable for vulnerable groups such as children, the elderly or people with disabilities. It is therefore advisable to adapt the maximum temperature to the needs of your audience.

- Cold water: keep temperature below 25°C to avoid bacterial growth.

DHW temperatures between 25°C and 59°C provide a favorable environment for bacterial proliferation. To ensure a balance between safety and comfort, it is therefore crucial for ERP systems to maintain temperatures outside this range.

Who is responsible for regulatory obligations?

The legal framework for domestic hot water temperatures in the ERP sector

Managers of public buildings (Établissements Recevant du Public - ERP) are subject to strict monitoring and traceability obligations to guarantee the sanitary safety of hot water. These obligations are defined in articles R.1321-1 et seq. of the French Public Health Code. Here are the main responsibilities incumbent upon them.

- Monitor the quality of produced and distributed water, including temperature.

- Submit to a sanitary inspection, in accordance with regulatory requirements.

- Take corrective action in the event of non-compliance or health risks, and inform users if necessary.

- Use safe treatment products and processes that have no negative impact on water quality.

- Comply with design and hygiene standards applicable to networks and installations.

- Interrupt or restrict distribution in the event of a health risk, providing appropriate advice to users.

- Implement a water safety management plan, including a risk assessment of ERP indoor networks.

Frequency of domestic hot water system temperature checks for DHW systems

| Monitoring point | Measures |

|---|---|

| After general meter (cold water) Point where water enters the building, before it is used or heated. | Recommended: once a week |

| DHW production outlet/return (distribution) Pipes leaving hot water production equipment (e.g. boilers, hot water tanks) to supply the network. | Mandatory: once a month for ERP Mandatory: once a day (or continuously) for healthcare facilities |

| Loop return (general return) The point at which the water returns to production after circulating throughout the network. | Mandatory: once a month for ERP Mandatory: once a day (or continuously) for healthcare facilities |

Who is affected by the obligation to monitor?

The monitoring of domestic hot water (DHW) concerns a wide range of establishments receiving the public (ERP), where DHW networks present an increased risk of legionella proliferation. The decree of February 1, 2010, based on articles L.1321-1 and L.1321-4 of the French Public Health Code, defines the obligations of these establishments. Here is a non-exhaustive list:

- Healthcare and medico-social establishments: Hospitals, clinics, follow-up care facilities, retirement homes, homes for the elderly or disabled

- Tourist and accommodation establishments: Hotels, tourist residences, campsites, vacation villages, large-capacity gîtes.

- Thermal and aquatic establishments: spas, public swimming pools, aquatic complexes, hammams, baths, spas and saunas open to the public.

- Educational and leisure facilities: boarding schools, middle schools, high schools with communal showers, leisure centers with sanitary facilities.

- Penitentiary and social facilities: prisons, rehabilitation centers, remand prisons.

These establishments are concerned if they use collective DHW networks, often associated with equipment that encourages the emission of aerosols (showers, baths, jets, etc.), or if they welcome a vulnerable public. For further details, the Grand Est information guide offers comprehensive expertise on the management of DHW systems and the preventive actions to be taken.

What solutions can simplify water temperature monitoring?

Managing domestic hot water temperature in an ERP system can become a simple and reliable process thanks to technological innovations. Ewattch, with its connected sensors and EwattchCloud platform, offers comprehensive solutions for monitoring, optimizing and maintaining your installations with complete peace of mind.

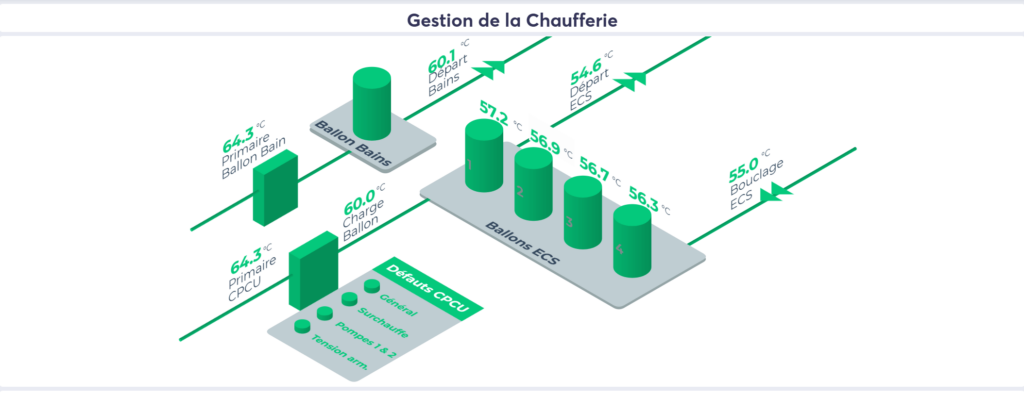

Real-time temperature monitoring

Ewattch's IoT sensors enable continuous monitoring of DHW temperatures at various strategic points in the network, including hot water tanks, loop returns, and remote distribution points. These data are transmitted in real time to the platform EwattchCloudplatform, an intuitive management tool accessible from a computer or cell phone.

Thanks to clear, dynamic dashboards, managers can instantly visualize temperatures and detect any deviation from recommended ranges. What's more, an automatic alert system provides immediate information in the event of a critical anomaly, such as a drop below 60°C, prolonged overheating, or a complete breakdown of key equipment such as a boiler or circulator.

Proactive prevention through predictive maintenance

Ewattch solutions integrate predictive maintenance functions based on the analysis of collected data. By studying temperature trends and anomalies, equipment can be monitored on a preventive basis.

Here's a concrete example: a recurring drop in temperature outside the recommended ranges may indicate an imminent circulator failure or a leak in the network. The platform identifies these weak signals well before the breakdown becomes critical, enabling repairs to be planned without bringing the plant to a standstill.

Predictive maintenance makes it possible toavoid costly interventions such as shock chlorination, which is necessary in the event of a prolonged drop in temperature below 60°C, which encourages bacterial proliferation. Although effective, this procedure is costly, immobilizes the network and cannot be carried out frequently.

Automated regulatory compliance

Legal obligations require ERP managers to document temperature readings and guarantee impeccable traceability. EwattchCloud makes this task simple and automatic.

- Secure data archiving: EwattchCloud stores all the information needed to prove compliance during health inspections.

- Programmable reports: detailed, customizable reports can be generated automatically and scheduled at regular intervals (weekly, monthly, etc.). These reports provide proof of compliance, reducing the stress of controls and the risk of sanctions.

Energy optimization and cost reduction

Energy optimization is a crucial issue for ERP systems. Ewattch sensors, combined with thermal mapping of installations, enable precise identification of energy losses. For example, incorrectly adjusted heating cycles or inadequate duct insulation can lead to costly over-consumption.

Thanks to real-time data supplied by sensors and centralized on the EwattchCloud platform, managers can analyze energy consumption in depth. This information enables them to :

- Adjust heating cycles: Reduce unnecessary times or temperatures, adjust hot water production according to actual needs, to minimize waste and significantly reduce operating costs.

- Identify areas of heat loss: Locate and map energy losses and inefficient areas of the network.

- Plan corrective actions: For example, adjust system settings during off-peak periods or replace energy-hungry equipment.

By optimizing these parameters, ERPs can not only reduce their energy bills, but also contribute to their corporate social responsibility objectives, by limiting their carbon footprint. This proactive approach guarantees sustainable savings while ensuring quality service for users.