Industry Solution

Smart Industry solution for energy performance

Industrial companies are facing major challenges in terms of productivity, against a backdrop of energy and regulatory issues. Ewattch provides effective solutions to meet these needs and transform the connected industry.

ISO50001 compliant

Reduces energy bills by up to 40%.

Controlling and prioritizing investments

Setting up action plans and monitoring consumption

Benefits

The ultimate solution

energy management

for Industry 4.0

Ewattch is asserting itself as a strategic ally for the industrial sector, providing digitalized and intelligent solutions that precisely meet the innovation needs of modern industries: reduction of the carbon footprint, reduction of energy bills, and commitment of teams to energy saving initiatives in particular

Compliance

Enables fast, efficient response to current and future regulatory requirements, including ISO 50001 compliance.

Fast

savings

Significantly reduce your energy bill by an average of 30% from the very first months, with a return on investment of less than 3 months.

Get started

today

An Ewattch expert will help you connect your general meter to the EwattchCloud IoT platform, and accompany you to build your project quickly with low initial investments.

Scalable software

& intuitive

EwattchCloud is an intuitive IoT platform, accessible on both computers and mobile devices, providing valuable information in real time and easy to use.

EwattchCloud

Team involvement

Complementing the platform, Ewattch offers a powerful visual management tool to engage your teams in improving and optimizing your company's energy efficiency.

Expert contact

& partners

Benefit from expert advice and support, as well as recognized expertise from our teams and partners.

Multi-site

Customize the platform to meet the specific needs of your different industrial sites and the teams who work there.

Made in France

Our production and design teams invest daily in product and software development in France, with the primary aim of promoting innovation and the excellence of French know-how.

Smart Industry goes further with our Ewattch network of complementary applications

Connected to our IOT platform, they enable you to enhance the management of your sites.

Technology

The infallible tool for making sound decisions and prioritizing actions

Your decisions to optimize your industry's energy management will now be based on your actual energy data, rather than on assumptions.

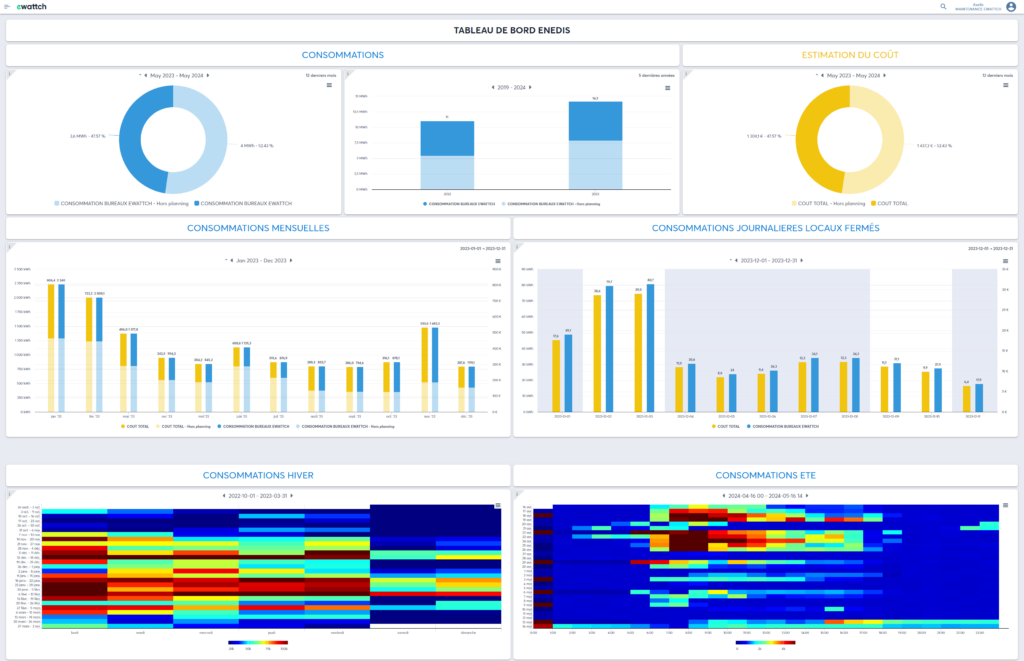

Enedis meter

Connection of the general meter to the Ewattch IoT platform via a simple online form, without the need to install additional IoT sensors.

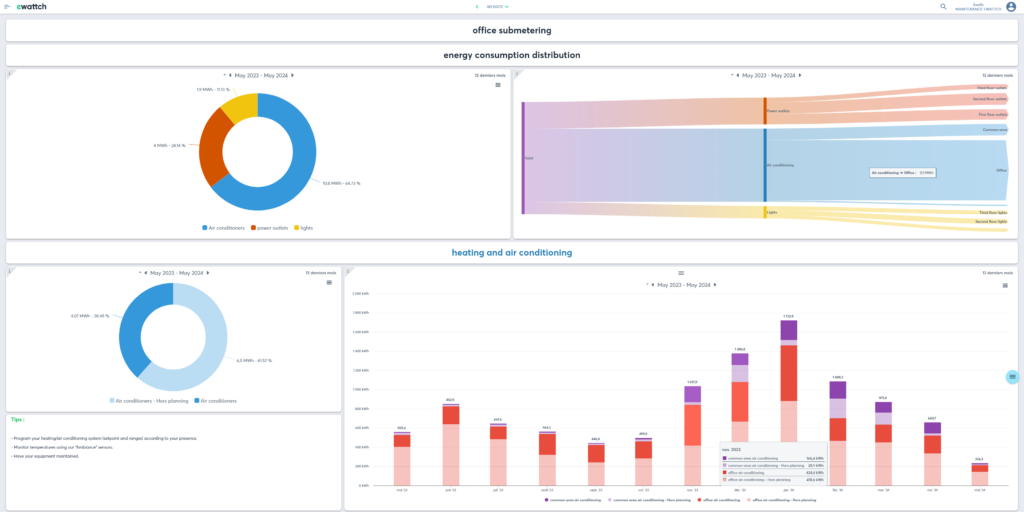

Squid

Detailed analysis of electricity consumption by zone and by use, precise detection of anomalies, strategic prioritization of actions, and calculation of return on investment (ROI).

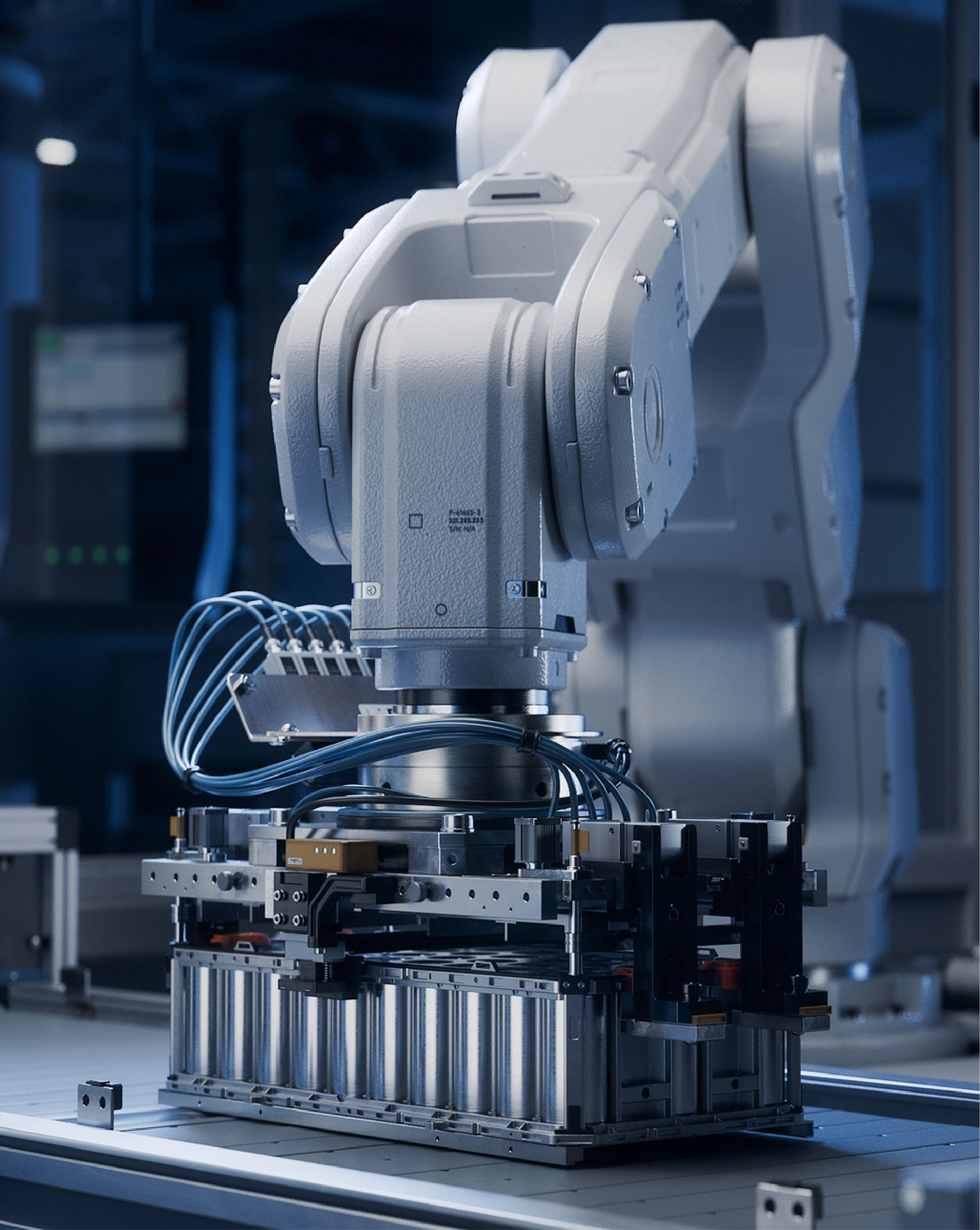

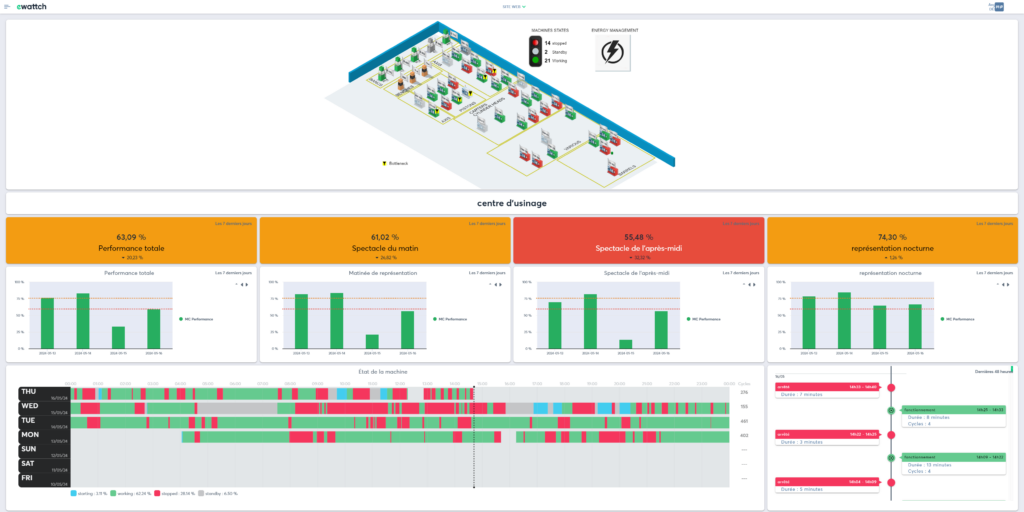

Tyness

Optimize the performance and energy consumption of your industrial equipment, such as compressors, chillers and industrial machines.

Would you like to

evaluate your savings potential?

Method

Progress towards

energy efficiency at your own pace

With Ewattch, you can optimize the energy efficiency of your industrial buildings in a targeted and cost-effective way, without the need for over-equipment.

Commissioning

Simple, fast and efficient

The fruit of several years' development and innovation, Ewattch presents an exclusive and effective technology: ScanToCloud. This innovation revolutionizes the deployment of energy management solutions by facilitating the connection between sensors and the IoT platform.

Rapid deployment

by your teams while

benefiting from Ewattch support.

ScanToCloud simplifies product integration with the EwattchCloud IoT platform, offering fast connection and facilitating instant energy monitoring.

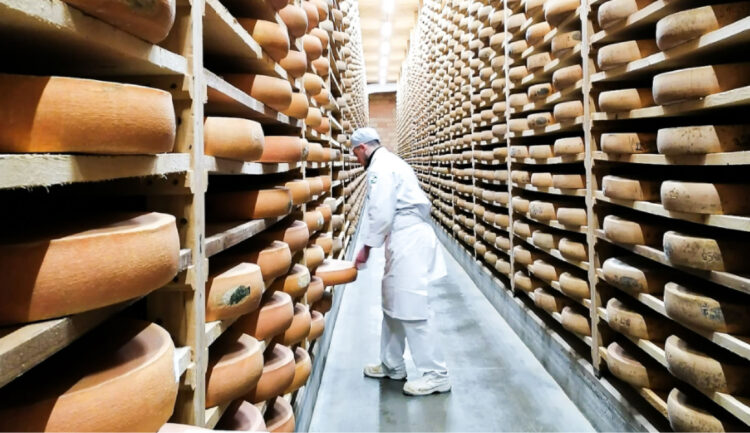

Testimonials

They have reduced their

bill and their carbon footprint.

Find out how Ewattch supports its customers to help them meet their challenges.

FAQ

All about Smart Industry

Industry 4.0: What is Smart Industry?

Smart Industry, or Industry 4.0, refers to the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and connected systems into industrial processes. This approach transforms traditional methods of production, manufacturing, and logistics by making them smarter, more flexible, and more responsive. By becoming Smart Industries, companies can improve efficiency, reduce costs, and optimize their processes for sustainable growth.

How can a Smart Industry solution optimize the energy management of my industrial site?

A Smart Industry solution makes it possible to centralize and automate the control of energy consumption through the use of IoT sensors connected to a management platform. Using technologies such as LoRa and LoRaWAN, these sensors detect and collect real-time data on the energy use of each machine or piece of equipment. This makes it possible to identify waste, prioritize corrective actions, and optimize systems to significantly reduce energy costs.

What are the benefits of Smart Industry in terms of productivity and performance?

Smart Industry improves the productivity and performance of industrial sites thanks to several key innovations:

- Optimization of production processes: Industrial automation helps improve the efficiency of operations.

- Predictive diagnostics and maintenance: IoT sensors detect anomalies before they become critical failures.

- Operator comfort: Intelligent systems adjust the working environment to maximize comfort and safety.

- Continuous improvement: AI continuously analyzes data to propose optimizations of industrial processes.

These advantages allow companies to maintain a high production rate while ensuring consistent quality.

ISO 500001, BACS decree, how does Smart Industry comply with standards and regulations?

Smart Industry helps companies comply with standards and regulations. This is the case in particular with the BACS decree which concerns tertiary buildings, or the obtaining of the ISO 50001 standard. These standards require rigorous energy management and continuous improvement in energy performance. Thanks to the integration of IoT sensors and industrial automation, Smart Industry solutions enable accurate and continuous monitoring of energy consumption. The data collected is centralized on an IoT platform, making it easier to implement corrective actions and optimize processes to achieve the goals set by these standards.

In compliance with ISO 50001, Smart Industry makes it possible to:

- Monitor and analyze energy consumption in real time.

- Implement action plans to reduce the energy footprint.

- Document and report improvements in accordance with regulatory requirements.

For the BACS decree, the connected systems of a Smart Industry allow the automation of controls and the optimization of equipment to ensure that the building complies with the imposed energy thresholds.

Are Smart Industry solutions cost-effective?

Reducing operating costs is one of the main benefits of Smart Industrie. As a result, return on investment is generally rapid and significant. By optimizing management of energy resources, reducing downtime through predictive maintenance, and improving productivity, companies can achieve significant savings. Connected systems also enable better inventory and logistics management, avoiding the extra costs associated with inefficiencies. Complementing IOT sensors, production process automation solutions can reduce labor costs and improve overall profitability.

What are the benefits of predictive maintenance in Smart Industry?

Predictive maintenance is a pillar of the Smart Industry. By using IoT sensors and AI algorithms, it is possible to continuously monitor the status of machines and equipment. These systems detect the warning signs of failures, allowing intervention to be taken before a failure occurs. This reduces maintenance costs, minimizes production interruptions, and extends equipment life. Predictive maintenance not only improves the reliability of operations, but it also contributes to the safety of the industrial site.

How do IoT sensors and the EwattchCloud platform connect in an industrial context?

In a Smart Industry, IoT sensors play a crucial role in collecting real-time data on various aspects of the industrial process. These sensors, often based on LoRa and LoRaWAN technologies, transmit the information to the EwattchCloud platform. This platform centralizes data, analyzes it, and provides actionable insights to optimize production, maintenance, and energy management. The connectivity between the IoT sensors and the platform enables integrated and intelligent management of the entire industrial system.

How does Smart Industry contribute to the security and surveillance of industrial sites?

Security and surveillance are major concerns in industrial environments. Smart Industry reinforces these aspects with connected systems that offer real-time monitoring. The sensors detect anomalies, dangerous conditions, or impending failures, allowing for quick reactions to avoid accidents. In addition, these systems help reduce operational risks by ensuring strict regulatory compliance and ensuring the safety of workers and infrastructure.

What types of industrial equipment can be integrated into a Smart Industry solution?

A Smart Industry solution can integrate a wide range of industrial equipment. To collect and analyze data in real-time, IoT sensors can be deployed, for example, on:

- Production machines,

- Packaging and packaging lines

- HVAC systems,

- Surveillance devices,

- Logistics equipment

- Measuring and quality control instruments

- IT and network infrastructures

The possibilities are in fact endless and rapidly evolving. This flexibility allows a traditional industrial site to be gradually transformed into a connected and intelligent environment, ready to meet the challenges of the connected industry. Ewattch's experts specialize in creating innovative and tailor-made solutions, adapted to the performance of each industry.